All Products

-

Stainless Steel Sheet Coil

-

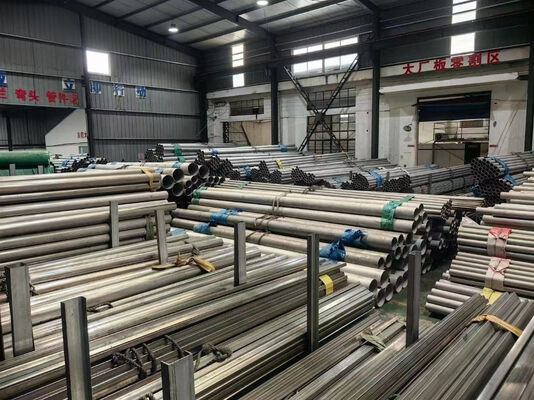

Stainless Steel Pipes

-

Stainless Steel Bar

-

Stainless Steel Strip

-

Stainless Steel Plate

-

Tin Plated Steel

-

304 Stainless Steel Sheet

-

316 Stainless Steel Sheet

-

Stainless Steel Coil

-

Alloy Aluminum Sheet

-

Aluminum Steel Coil

-

Galvanized Steel Coils

-

PPGI Steel Sheet

-

PPGI Steel Coil

-

Copper Round Rod

-

Copper Alloy Sheet

-

Copper Round Pipe

-

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย -

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time -

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

Cold Rolled Stainless Steel Tube Ni 8-12 Percent AISI 304 304L Capillary Inox Tube 316L 201 202 Round Square Rectangular

Product Details

| Model NO. | Stainless Steel Pipe | Shape | Round |

|---|---|---|---|

| Technique | Cold Rolled | Surface Treatment | Polished |

| Applications | Architectural Decoration | Product Name | Stainless Steel Pipe |

| Surface Finish | 2b,Ba,No.1,No.4,4K,8K,Mirror | Tolerance | 1% |

| Ni | 8-12% | Materials | 201,304,321,316ti,316L,314h,310S,2507 |

| Transport Package | Water Proof Paper+Metal Pallet+Angle Bar Protectio | Specification | As Requirement |

| Trademark | TISCO, POSCO, JISCO, LISCO Etc. | Origin | Wuxi China |

| HS Code | 721922 | Supply Ability | 50000ton/Month |

| Highlight | cold rolled stainless steel tube,AISI 304 stainless steel pipe,316L stainless steel capillary tube |

||

Product Description

Cold Rolled Stainless Steel Tube Ni 8-12 Percent AISI 304 304L Capillary Inox Tube 316L 201 202 Round Square Rectangular

304 Stainless Steel Capillary Tube 1.0mm-1.6mm Stainless Steel Precision Tube

321 stainless steel pipe (UNS S32100) is a titanium-stabilized austenitic stainless steel pipe derived from 304 stainless steel, with titanium added to suppress intergranular corrosion caused by chromium carbide precipitation. It excels in high-temperature resistance, corrosion resistance, and mechanical stability, making it a preferred choice for harsh-environment applications such as industrial high-temperature pipelines and chemical processing equipment.

Core Product Overview & Standards

Key Grades:

- 321 (UNS S32100): Standard grade with a maximum carbon content of 0.08%, optimized for general high-temperature and corrosion-resistant scenarios

- 321H (UNS S32109): High-carbon variant (carbon content 0.04-0.10%) designed for enhanced creep resistance and strength at temperatures above 537°C (1000°F)

International Standards:

- ASTM/ASME: A312/SA312 (seamless/welded stainless steel pipes), B36.10M/B36.19M (dimensional specifications)

- DIN: 1.4541 (equivalent material number)

- JIS/SUS, GB, AISI (regional mainstream standards)

Key Technical Parameters

Chemical Composition (Weight %):

| Element | C | Si | Mn | Cr | Ni | S | P | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 321 | ≤0.08 | ≤0.75 | ≤2.0 | 17.0-19.0 | 9.0-12.0 | ≤0.03 | ≤0.045 | 5×(C+N)-0.70 | Balance |

| 321H | 0.04-0.10 | ≤0.75 | ≤2.0 | 17.0-19.0 | 9.0-12.0 | ≤0.03 | ≤0.045 | 5×(C+N)-0.70 | Balance |

Mechanical Properties (Annealed State):

| Grade | Tensile Strength (MPa, min) | Yield Strength (σ0.2, MPa, min) | Elongation (δ5, %, min) | Hardness (max) |

|---|---|---|---|---|

| 321 | 520 | 205 | 40 | 187 HB / 90 HRB / 200 HV |

| 321H | 520 | 205 | 40 | 217 HB |

Physical Properties:

- Density: 7.93 g/cm³ (0.286 lbm/in³)

- Operating Temperature Range: -270°C (cryogenic) to 816°C (oxidation-resistant up to 1500°F)

- Thermal Expansion Coefficient: 9.2×10/°C (68-212°F)

- Modulus of Elasticity: 200 GPa (28×10 psi) at 20°C

Dimensional Specifications:

| Type | Outer Diameter (OD) | Wall Thickness | Length | End Types |

|---|---|---|---|---|

| Seamless Pipe | 6 mm - 914.4 mm | 2.5 mm - 30 mm | 6-12 m (customizable) | Plain end, beveled end, threaded |

| Welded Pipe (ERW/SAW) | 9.5 mm - 1200 mm | 0.3 mm - 40 mm | 6-12 m (customizable) | Plain end, butt weld end |

| Shapes | Round, square, rectangular, hexagonal, U-shaped | |||

| Schedules | Sch 5, Sch 10, Sch 40, Sch 80, Sch 160, XXS, etc. | |||

Core Performance Advantages

- Superior High-Temperature Stability: Resists oxidation at 816°C and offers better creep and stress rupture properties than 304/304L

- Intergranular Corrosion Resistance: Titanium stabilization prevents chromium depletion in the 427-816°C range, avoiding intergranular corrosion even after welding or heat treatment

- Broad Corrosion Resistance: Comparable to 304 in general corrosion resistance; suitable for dilute organic acids, pure phosphoric acid (low temperature), and 10% dilute acid solutions (high temperature)

- Excellent Toughness: Maintains good low-temperature toughness (down to cryogenic levels) and formability

Typical Applications

- Aerospace: Aircraft piston engine manifolds, exhaust stacks

- Petrochemical & Refining: Heat exchangers, furnace parts, refinery pipelines, expansion joints

- Chemical Industry: High-temperature chemical process equipment, pipelines for dilute acids

- Energy & Power: Thermal oxidizers, boiler tubes, and high-temperature flue gas pipelines

- Food & Pharmaceutical: Food processing equipment, brewery pipelines, and pharmaceutical machinery

- Mechanical Engineering: Auto parts, structural components, and furniture/kitchenware

Limitations & Selection Notes

- Chloride Sensitivity: Not suitable for chloride-rich environments or sulfuric acid solutions

- Machinability: Titanium addition reduces machinability compared to 304

- Grade Selection: Choose 321 for temperatures ≤537°C; opt for 321H for long-term service above 537°C

- Certifications: Prioritize products with ISO, SGS, or BV certifications

Manufacturing & Quality Control

- Processes: Hot rolling, cold rolling (seamless), electric resistance welding (ERW), submerged arc welding (SAW)

- Surface Treatments: Black oxide, pickling, polished (No.4/BA), satin, mirror finish, electropolishing

- Mandatory Inspections: Hydrostatic pressure testing, non-destructive testing, chemical composition analysis, and mechanical property testing

Detailed Photos

Surface Finishes

Packaging & Shipping

Company Profile

Our company offers variety of products which can meet your multifarious demands. We adhere to the management principles of "quality first, customer first and credit-based", since the establishment of the company and always to do our best to satisfy potential needs of our customers. Our company is sincerely to willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with irresistible force.

Quality Control

Certifications

Frequently Asked Questions

Q1: Why choose us?

Our company, as an internationally experienced and professional supplier, has been engaged in steel business for more than ten years. We can provide a variety of steel products with high quality to our clients.

Q2: Can you provide OEM/ODM service?

Yes. Please feel free to contact us for more details.

Q3: What is your terms of payment?

100% T/T advance.

30% T/T and balance against copy of documents.

30% T/T advance, balance L/C at sight.

30% T/T and balance against copy of documents.

30% T/T advance, balance L/C at sight.

Q4: Can we visit your factory?

Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q5: Can you provide sample?

Yes. Sample is free for regular sizes, but the buyer needs to pay freight cost.

Q6: How long is your delivery time?

Regular lead time is 15 to 30 days after receiving deposit.

Recommended Products