All Products

-

Stainless Steel Sheet Coil

-

Stainless Steel Pipes

-

Stainless Steel Bar

-

Stainless Steel Strip

-

Stainless Steel Plate

-

Tin Plated Steel

-

304 Stainless Steel Sheet

-

316 Stainless Steel Sheet

-

Stainless Steel Coil

-

Alloy Aluminum Sheet

-

Aluminum Steel Coil

-

Galvanized Steel Coils

-

PPGI Steel Sheet

-

PPGI Steel Coil

-

Copper Round Rod

-

Copper Alloy Sheet

-

Copper Round Pipe

-

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย -

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time -

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

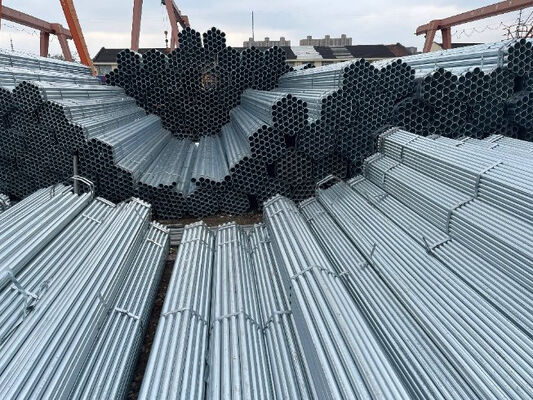

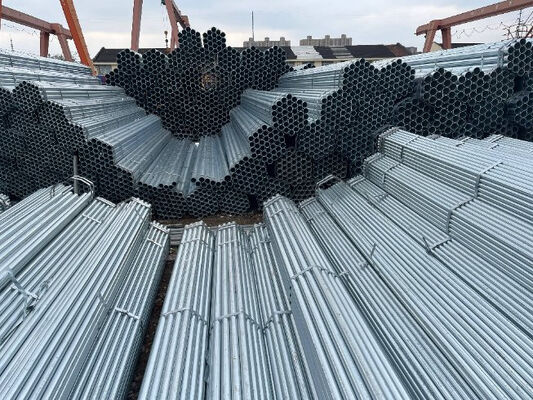

Galvanized Steel Pipe Thickness 1mm to 12mm ASTM JIS Q235 S235jr S355j2 Round Square Welded Seamless Carbon Stainless Steel

Product Details

| Model NO. | A53 | Technique | Hot Rolled |

|---|---|---|---|

| Material | Galvanzied Steel Pipe | Surface Treatment | Hot Rolling |

| Usage | Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose | Section Shape | Square |

| Standard | ASTM A53-2007, ASTM A671-2006, ASTM A252-1 | Delivery Time | 7-15days |

| Thickness | 1mm-12mm | Length | 5m-14m,5.8m,6m,10m-12m,12m |

| Surface | Galvanzied | Transport Package | Water Proof Paper+Metal Pallet+Angle Bar Protectio |

| Specification | As Requirement | Trademark | TISCO, POSCO, JISCO, LISCO Etc. |

| Origin | China | HS Code | 7208512000 |

| Supply Ability | 50000ton/Month | ||

| Highlight | galvanized steel pipe 1mm to 12mm,welded seamless carbon steel pipe,stainless steel pipe ASTM JIS |

||

Product Description

Factory Hot Sale Galvanized Steel Pipe

Galvanized steel pipe is a specialized tubular product manufactured by applying a zinc coating to the surface of carbon steel pipes through hot-dip or electroplating processes. The zinc coating forms a sacrificial anode protection layer, effectively isolating the steel substrate from air and moisture, thereby significantly enhancing corrosion resistance. With the advantages of cost-effectiveness, reliable mechanical properties, and easy installation, it is widely used in construction, water supply and drainage, fire protection, agricultural irrigation, and industrial fluid transportation.

Core Classification

By Galvanizing Process

| Galvanizing Process | Coating Formation | Zinc Coating Index | Core Properties | Service Life | Application Scope |

|---|---|---|---|---|---|

| Hot-Dip Galvanizing (HDG) | Immerse pickled steel pipes in molten zinc (440-460ºC) | Thickness: ≥80μm (average ≥640g/m²) | Strong coating adhesion, excellent corrosion resistance, wear-resistant | 20-50 years (outdoor environment) | Fire protection pipes, water supply pipes, structural supports, marine engineering |

| Electro-Galvanizing (EG) | Deposit zinc ions through electrolysis | Thickness: 10-50μm (10-50g/m²) | Weak adhesion, poor corrosion resistance, easy to peel off | 3-8 years (indoor dry environment) | Indoor decorative pipes, non-critical low-pressure fluid pipes |

By Base Steel Grade

- Common Carbon Steel Grades: Q195/Q215 (low strength), Q235 (balanced), Q345 (high strength)

- Special Function Grades: Anti-corrosion alloy steel, high-temperature resistant steel, low-temperature resistant steel

Technical Specifications & Standards

Critical Technical Parameters (Hot-Dip Galvanized)

| Parameter Category | Typical Range (Q235 HDG) | Measurement Standard |

|---|---|---|

| Outer Diameter (OD) | DN15 (φ21.3mm) - DN300 (φ323.9mm) | ASTM A53, GB/T 3091 |

| Wall Thickness (WT) | 1.2mm - 12.0mm | ASTM A53, EN 10255 |

| Length | 6m/12m (standard); 3-18m (customizable) | Customer requirement |

| Mechanical Properties | Tensile strength: 375-500MPa; Yield strength: ≥235MPa | ASTM A53, GB/T 3091 |

| Zinc Coating Performance | Adhesion: No peeling after 180° bending | ASTM B117, ISO 9227 |

International Standards

- North America: ASTM A53/A53M, ASTM A123

- Europe: EN 10255, EN ISO 1461

- China: GB/T 3091-2015, GB/T 13912

- Japan: JIS G3444, JIS G3302

Application Scenarios

- Construction & Municipal Engineering: Fire protection systems, water supply, structural supports

- Agriculture & Irrigation: Farm irrigation, sprinkler systems

- Industrial Fluid Transport: Low-pressure oil, chemical reagents, high-pressure air

- Marine & Coastal Engineering: Seawater cooling systems, coastal building water supply

- Decorative & Furniture: Indoor railings, furniture frames

Quality Control & Procurement

Key Procurement Terms

- Clearly specify "hot-dip galvanized" (HDG) or "electro-galvanized" (EG)

- Define base steel grade and specifications

- Specify minimum zinc coating thickness for critical applications

- Request certification and documentation (MTR, ISO 9001, third-party inspection)

- Proper packaging and marking for transport

Quality Inspection Focus

- Visual inspection for zinc coating defects

- Dimensional and coating thickness testing

- Adhesion and corrosion testing

- Mechanical and pressure testing

Product Images

Frequently Asked Questions

Q1: Why choose us?

Our company, as an internationally experienced and professional supplier, has been engaged in steel business for more than ten years. We can provide a variety of steel products with high quality to our clients.

Q2: Can you provide OEM/ODM service?

Yes. Please feel free to contact us for more details.

Q3: What is your terms of payment?

100% T/T advance. 30% T/T and balance against copy of documents. 30% T/T advance, balance L/C at sight.

Q4: Can we visit your factory?

Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q5: Can you provide sample?

Yes. Sample is free for regular sizes, but the buyer needs to pay freight cost.

Q6: How long is your delivery time?

Regular lead time is 15 to 30 days after receiving deposit.

Recommended Products