-

Stainless Steel Sheet Coil

-

Stainless Steel Pipes

-

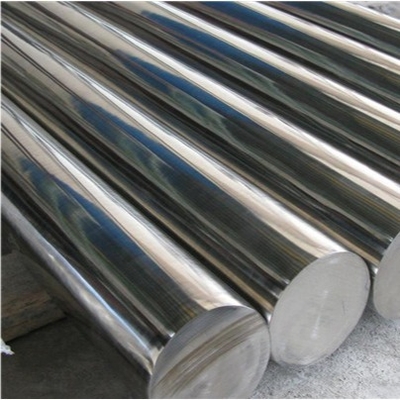

Stainless Steel Bar

-

Stainless Steel Strip

-

Stainless Steel Plate

-

Tin Plated Steel

-

304 Stainless Steel Sheet

-

316 Stainless Steel Sheet

-

Stainless Steel Coil

-

Alloy Aluminum Sheet

-

Aluminum Steel Coil

-

Galvanized Steel Coils

-

PPGI Steel Sheet

-

PPGI Steel Coil

-

Copper Round Rod

-

Copper Alloy Sheet

-

Copper Round Pipe

-

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย -

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time -

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

High Temperature Inconel Bar Rod 600mm Corrosion Resistant Structural Materials

| Place of Origin | CHINA |

|---|---|

| Brand Name | TISCO |

| Certification | ISO9001,CE,RoHS |

| Model Number | Inconel 600 601 625 718 X750 |

| Minimum Order Quantity | 1 Ton |

| Price | According To The Quantity |

| Packaging Details | Standard Seaworthy Package |

| Delivery Time | 7-10days |

| Payment Terms | 30%L/C + 70%T/T |

| Supply Ability | 50000 Tons Per Year |

| Application | High Temperature Corrosion Resistance | Ni (Min) | 50% |

|---|---|---|---|

| Powder Or Not | Not Powder | Elongation (≥ %) | 28 |

| Heat Treatment Method | Solid Solution And Aging Treatment | Feature | High Temperature Corrosion Resistant |

| Highlight | High temperature Inconel Bar,600mm Inconel Bar rod,Inconel Bar corrosion resistance |

||

Inconel 600 601 625 718 X750 Bar/Rod For Corrosion Resistant Structural Materials

Inconel 600 alloy is a nickel-chromium-iron-based solid solution strengthened alloy with good high temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding properties, and has satisfactory thermal strength and high plasticity below 700 ℃. Inconel 600 material is the most commonly used material in structural engineering because it is well suited for high temperatures above 1000°F (540°C). Inconel 600 is durable, stable, strong and corrosion resistant. Inconel 600 is also known as a superalloy due to its strong properties, such as its excellent performance under enormous mechanical stress and temperature, and its resistance to oxidation and creep. Inconel 600 (UNS N06600) is also used in parts and accessories for heat treatment furnaces, heat exchangers, etc.

| Product Name | Inconel 600 601 625 718 X750 Bar/Rod For Corrosion Resistant Structural Materials |

| Type: | Bar/Rod |

| Outer Diameter | 10-600mm (3/8"-25") |

| Length | 3000mm, 5800mm, 6000mm,12000mm,etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,HL |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. |

| It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. | |

| Certification | ISO, SGS, BV |

| Technique | Cold Rolled /Hot Rolled/ Casting |

| Edge | Mill Edge/Slit Edge |

| Grade (ASTM UNS) | N08020,INCOLOY Alloy 20, N08028,INCOLOY Alloy 28, N08330,INCOLOY, Alloy 330, N08800, INCOLOY Alloy 800, N08810, INCOLOY Alloy 800H, N08825, INCOLOY Alloy 825, N06600, Inconel 600, N06601, Inconel 601, N06625, Inconel 625, INCOLOY Alloy 625, N07718, Inconel 718,INCOLOY Alloy 718,N07750,Inconel X750,N04400,MONEL400, Nickl200, S66286, N10276, Hastelloy C-276, N06455, Hastelloy C-4,N06022,Hastelloy C-22,N10665,Hastelloy B-2,N10675, Hastelloy B-3, N06030, Hastelloy G-30, INCOLOY Alloy A286, N08926, INCOLOY Alloy 25-6Mo etc. |

| Grade (EN) | 2.4060 1.4980 1.4529 2.4460 1.4563 1.4886 1.4876 1.4876 2.4858,2.4816 2.4851 2.4856 2.4856 2.4668 2.4669 2.4360 2.4375 2.4819 2.4610 2.4602 2.4617 2.4660 etc. |

| Packaging Details | In bundle,plastic bags,thin film,wooden pallet,standard seaworthy export packing or as customer demands |

| Container Dimension | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM |

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM | |

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

Chemical Composition

| Grade | Ni,Min | Cu | Mo | Mn | C | Si | S | Cr | Al | Ti | V | Nb |

| UNS N02200 | 99.0 | 0.25 | - | 0.35 | 0.15 | 0.35 | 0.001 | - | - | - | - | - |

| N04400 (Monel400) |

63.0 | 28.0-34.0 | - | 2.00 | 0.30 | 0.50 | 0.024 | - | - | - | - | - |

| UNS N06600 (Inconel600) |

72.0 | 0.50 | - | 1.00 | 0.15 | 0.50 | 0.015 | 14.0-17.0 | - | - | - | - |

| UNS N06601 (Inconel601) |

58.0-63.0 | 1.00 | - | 1.00 | 0.10 | 0.50 | 0.015 | 21.0-25.0 | 1.0-1.7 | - | - | - |

| UNS N06625 (Inconel625) |

58.0 | - | 8.0-10.0 | 0.5 | 0.10 | 0.50 | 0.015 | 20.0-23.0 | 0.40 | 0.40 | - | Nb+Ta:3.15-4.15 |

| UNS N06690 (Inconel690) |

58.0 | 0.50 | - | 0.5 | 0.50 | 0.50 | 0.015 | 27.0-31.0 | - | - | - | - |

| UNS N08020 (Alloy 20) |

32.0-38.0 | 3.0-4.0 | 2.0-3.0 | 2.0 | 0.07 | 1.00 | 0.035 | 19.0-21.0 | - | - | - | Nb+Ta:8xC-1.00 |

| UNS N08028 (Alloy 28) |

30.0-34.0 | 0.6-1.4 | 3.0-4.0 | 2.5 | 0.03 | 1.00 | 0.030 | 26.0-28.0 | - | - | - | - |

| UNS N08800 (Incoloy800) |

30.0-35.0 | 0.75 | - | 1.5 | 0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - |

| UNS N08810 (Incoloy800H) |

30.0-35.0 | 0.75 | - | 1.5 | 0.05-0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - |

| UNS N08811 (Incoloy800HT) |

30.0-35.0 | 0.75 | - | 1.5 | 0.06-0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - |

| UNS N08825 (Incoloy825) |

38.0-46.0 | 1.5-3.0 | 2.5-3.5 | 1.0 | 0.05 | 0.50 | 0.030 | 19.5-23.5 | 0.20 | 0.6-1.2 | - | - |

| UNS N06022 (Hastelloy C-22) |

Surplus | - | 12.5-14.5 | 0.5 | 0.015 | 0.08 | 0.020 | 20.0-22.5 | - | - | 0.35 | - |

| UNS N10276 (Hastelloy C-276) |

Surplus | - | 15.0-17.0 | 1.0 | 0.01 | 0.08 | 0.030 | 14.5-16.5 | - | - | - | - |

| UNS N10665 (Hastelloy B-2) |

Surplus | - | 26.0-30.0 | 1.0 | 0.02 | 0.10 | 0.030 | 1.00 | - | - | - | - |

| UNS N10673 (Hastelloy B-3) |

65.0 | - | 27.0-32.0 | 3.0 | 0.01 | 0.10 | 0.010 | 1.0-3.0 | - | - | 0.20 | 0.02 |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Ductility | HRB |

| UNS N02200 | ||||

| Anneales | 379 | 103 | 40 | - |

| Stress-relieved | 448 | 276 | 15 | B65 |

| N04400(Monel400) | ||||

| Anneales | 483 | 193 | 35 | - |

| Stress-relieved | 586 | 378 | 15 | B65 |

| UNS N06600(Inconel600) | 552 | 241 | 30 | - |

| UNS N06601(Inconel601) | 552 | 207 | 30 | - |

| UNS N06625(Inconel625) | ||||

| Gr.1 | 827 | 414 | 30 | - |

| Gr.2 | 690 | 276 | 30 | - |

| UNS N06690(Inconel690) | 586 | 241 | 30 | - |

| UNS N08020(Alloy 20) | 551 | 241 | 30 | - |

| UNS N08028(Alloy 28) | 500 | 214 | 40 | - |

| UNS N08800(Incoloy800) | ||||

| Annealed | 518 | 207 | 30 | - |

| Cold-Worked | 572 | 324 | 30 | - |

| UNS N08810(Incoloy800H) | 448 | 172 | 30 | - |

| UNS N08811(Incoloy800HT) | 448 | 172 | 30 | - |

| UNS N08825(Incoloy825) | 241 | 586 | 30 | - |

| UNS N06022(Hastelloy C-22) | 690 | 310 | 45 | - |

| UNS N10276(Hastelloy C-276) | 690 | 283 | 40 | - |

| UNS N10665(Hastelloy B-2) | 760 | 350 | 40 | - |

| UNS N10673(Hastelloy B-3) | 760 | 350 | 40 | - |

Detail Photos

![]()

Certification

![]()

Packing & Shipping

![]()

FAQ

Q1: ARE YOU FACTORY OR TRADER?

A1: Our company is a cold rolling manufacturer of magnetic stainless steel coil since 2009. We've gained our Export Right and become an integrated company of industry and trade in order to satisfy buyer's multi-request on different material and products.

Q2: WHICH MATERIAL/PRODUCTS YOU CAN PROVIDE?

A2: Stainless Steel Coils / Strips, Stainless Steel Sheets / Plates, Stainless Steel Circles / Discs, Decorative Stainless Steel Sheets.

Q3: HOW TO GET A SAMPLE?

A3: FREE samples are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

Q4: HOW TO VISIT YOUR FACTORY?

A4: Most of the main cities have flights to Wuxi; you can take flight to Wuxi Shuofang International Airport.

If you come from Shanghai, it will take 2 hours by flight (every day 5 flights).

If you come from Hongkong, it will take 1 hour by flight (every day 1 flight around noon time).