-

Stainless Steel Sheet Coil

-

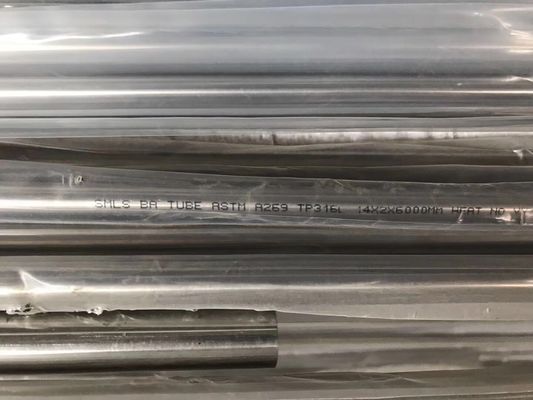

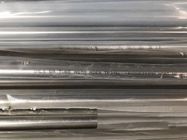

Stainless Steel Pipes

-

Stainless Steel Bar

-

Stainless Steel Strip

-

Stainless Steel Plate

-

Tin Plated Steel

-

304 Stainless Steel Sheet

-

316 Stainless Steel Sheet

-

Stainless Steel Coil

-

Alloy Aluminum Sheet

-

Aluminum Steel Coil

-

Galvanized Steel Coils

-

PPGI Steel Sheet

-

PPGI Steel Coil

-

Copper Round Rod

-

Copper Alloy Sheet

-

Copper Round Pipe

-

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย

Mr. ZailaniHastelloy C2076 ตัดโลหะผสมส่งและปลีกส่งเร็วมากบริการหลังการขายดีมากบริการออนไลน์ตลอด 24 ชั่วโมงความร่วมมือมีความสุขมากซื้อหลาย -

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time

Mr. ThomasTheir package and bags is very well, and the quantity is met requirement, good cooperation at first time -

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

Miss AmandaTheir Stainless steel sheet quality is prime, delivery is on time, perfect stainless steel supplier

500MM TiF6 TiAl4 Titanium Alloy Bars Stainless Steel Round Rod AISI

| Place of Origin | Mainland China |

|---|---|

| Brand Name | TISCO |

| Certification | SGS ISO ROHS |

| Model Number | TiAl 4 TiO 2 K 2 TiF 6 |

| Minimum Order Quantity | 100KG |

| Price | 500-1000 USD PER TON |

| Packaging Details | Standard Seaworthy Package |

| Delivery Time | 5-10Days after confirming order |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 30TONGS PER MONTH |

| Product Name | Titanium Alloy Bars | Standard | ASTM AISI GB DIN JIS EN |

|---|---|---|---|

| Processing Service | Bending Cutting Welding Punching | Diameter | 4-500mm |

| Length | 1m-12m As Requirements | Tolerance | 0.1mm |

| Heat Treatment | Annealing Tempered Quenched | Testing | Third Party Inspection Available |

| Highlight | 500MM Titanium Alloy Bars,TiF6 TiAl4 Titanium Alloy Bars,stainless steel round rod AISI |

||

ASTM 99.9% Purity Titanium bar Polished Titanium Alloy Bars Laser cutting

Titanium alloy was widely used in the field of aerospace in the early stage, mainly in making aircraft engines or pneumatic components. Later, with the continuous in-depth development of technology, titanium alloy has entered the lives of ordinary people, and there are titanium alloys in factories or household devices. Now, many countries and institutions are competing to develop new titanium alloys with the characteristics of low cost and high performance. In recent years, the new development of titanium alloys mainly focuses on the following five aspects.

(1) Medical titanium alloy

Titanium alloy has low density and good biocompatibility. It is an ideal medical material and can even be implanted into the human body. The titanium alloy previously used in the medical field contains vanadium and aluminum, which will do harm to the human body. However, recently, Japanese scholars have developed a new type of titanium alloy with good biocompatibility, but at present, this alloy has not been mass produced. It is believed that this kind of high-quality alloy can be widely used in daily life in the near future.

(2) Flame retardant titanium alloy

Titanium based alloys that can resist combustion under certain pressure, temperature and air flow rate are flame retardant titanium alloys. The United States, and China have successively developed new flame retardant titanium alloys. The United States applies these flame retardant titanium alloys to the engine. Because these titanium alloys are not sensitive to combustion, they can greatly improve the stability of the engine.

(3) High strength and toughness β type

β Type titanium alloy has the characteristics of high strength, good weldability and excellent cold and hot workability. The researchers used this law to prepare β The characteristics of T-type titanium alloy are very obvious: good hot working performance, good plasticity and good welding performance. The mechanical properties are greatly improved after solid solution aging treatment. At present, such titanium alloys have been prepared in Japan and .

(4) Titanium aluminum compound

Compared with ordinary titanium alloys, titanium aluminum compounds have good high temperature performance, good oxidation and creep resistance, and the density is less than that of ordinary titanium alloys. These excellent characteristics doomed that titanium aluminum compounds would set off a new alloy boom. At present, this new titanium aluminum compound alloy has been synthesized in the United States and is in mass production.

(5) High temperature titanium alloy

Titanium alloys prepared by combining rapid solidification method with powder metallurgy method and using fiber or particle reinforced composites have excellent high temperature mechanical characteristics. The service temperature limit of high temperature titanium alloy is much higher than that of ordinary titanium alloy. At present, new high temperature titanium alloys have been prepared in the United States.

(6) Titanium nickel alloy

The alloy composed of titanium and nickel is called "memory alloy". This alloy is made into a predetermined shape. After setting treatment, if it is deformed by external force, it can recover its original appearance as long as it is heated slightly. This alloy can be used in various fields such as instruments and electronic devices.

Bright Annealing ASTM Hastelloy C276 Rod diameter 16mm alloy Hastelloy Rod Medical Inconel Alloy 625 Bar

Equivalent designations

UNS N10276

DIN W. Nr. 2.4819

Bright Annealing ,Hastelloy C276 alloy Seamless Stainless Steel TubeFeatures: Hastelloy C-276 has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and

reducing media, thus making it suitable for a wide variety of chemical process environments, including ferric and cupric

chlorides, hot contaminated media (organic and inorganic), formic and acetic acids, seawater and brine solutions. It is one of the

few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.Applications: Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering.

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications. Inconel 625 was developed in the 1960s with the purpose of creating a material that could be used for steam-line piping. Some modifications were made to its original composition that have enabled it to be even more creep-resistant and weldable. Because of this, the uses of Inconel 625 have expanded into a wide range of industries such as the chemical processing industry, and for marine and nuclear applications to make pumps and valves and other high pressure equipment.

Inconel series: 600,601,617,625,690,718,X-750,825

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

| Inconel 601 625 718 750 800 800H 926 Price | |

| Grade | 601 625 718 750 800 800H 926 |

| Diameter Of Alloy bar | Hot Rolled: Φ8-38mm |

| Forging: Φ38-350mm | |

| Cold Rolled: ≤50mm | |

| Standard | ASTM AMSE YB HB BJB GB etc |

| Length | As Required |

| Surface | Black or Bright |

| Manufacture Technology | Hot Rolled ,Forging , Cold Rolled |

| Package | wooden boxes package,pvc package, and other package |

Chemical Component

| Grade | Ni,Min | Cu | Mo | Fe | Mn | C | Si | S | Cr | Al | Ti | P | V | Nb | Ta | Co | W |

| UNS N02200 | 99.0 | 0.25 | - | 0.40 | 0.35 | 0.15 | 0.35 | 0.001 | - | - | - | - | - | - | - | - | - |

|

N04400 (Monel400) |

63.0 | 28.0-34.0 | - | 2.50 | 2.00 | 0.30 | 0.50 | 0.024 | - | - | - | - | - | - | - | - | - |

|

UNS N06600 (Inconel600) |

72.0 | 0.50 | - |

6.0- 10.0 |

1.00 | 0.15 | 0.50 | 0.015 | 14.0-17.0 | - | - | - | - | - | - | - | - |

|

UNS N06601 (Inconel601) |

58.0-63.0 | 1.00 | - |

Sur plus |

1.00 | 0.10 | 0.50 | 0.015 | 21.0-25.0 | 1.0-1.7 | - | - | - | - | - | - | - |

|

UNS N06625 (Inconel625) |

58.0 | - | 8.0-10.0 | 5.0 | 0.5 | 0.10 | 0.50 | 0.015 | 20.0-23.0 | 0.40 | 0.40 | 0.015 | - | Nb+Ta:3.15-4.15 | 1.0 | - | |

|

UNS N06690 (Inconel690) |

58.0 | 0.50 | - |

7.0- 11.0 |

0.5 | 0.50 | 0.50 | 0.015 | 27.0-31.0 | - | - | - | - | - | - | - | - |

|

UNS N08020 (Alloy 20) |

32.0-38.0 | 3.0-4.0 | 2.0-3.0 |

Sur plus |

2.0 | 0.07 | 1.00 | 0.035 | 19.0-21.0 | - | - | 0.045 | - | Nb+Ta:8xC-1.00 | - | - | |

|

UNS N08028 (Alloy 28) |

30.0-34.0 | 0.6-1.4 | 3.0-4.0 |

Sur plus |

2.5 | 0.03 | 1.00 | 0.030 | 26.0-28.0 | - | - | 0.030 | - | - | - | - | - |

|

UNS N08800 (Incoloy800) |

30.0-35.0 | 0.75 | - |

39.5, Min |

1.5 | 0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - | - | - | - | - |

|

UNS N08810 (Incoloy800H) |

30.0-35.0 | 0.75 | - |

39.5 ,Min |

1.5 | 0.05-0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - | - | - | - | - |

|

UNS N08811 (Incoloy800HT) |

30.0-35.0 | 0.75 | - |

39.5 ,Min |

1.5 | 0.06-0.10 | 1.00 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 | - | - | - | - | - | - |

|

UNS N08825 (Incoloy825) |

38.0-46.0 | 1.5-3.0 | 2.5-3.5 |

22.0 ,Min |

1.0 | 0.05 | 0.50 | 0.030 | 19.5-23.5 | 0.20 | 0.6-1.2 | - | - | - | - | - | - |

|

UNS N06022 (Hastelloy C-22) |

Surplus | - | 12.5-14.5 |

2.0 -6.0 |

0.5 | 0.015 | 0.08 | 0.020 | 20.0-22.5 | - | - | 0.020 | 0.35 | - | - | 2.5 |

2.5 -3.5 |

|

UNS N10276 (Hastelloy C-276) |

Surplus | - | 15.0-17.0 |

4.0 -7.0 |

1.0 | 0.01 | 0.08 | 0.030 | 14.5-16.5 | - | - | 0.040 | - | - | - | 2.5 |

3.0 -4.5 |

|

UNS N10665 (Hastelloy B-2) |

Surplus | - | 26.0-30.0 | 2.0 | 1.0 | 0.02 | 0.10 | 0.030 | 1.00 | - | - | 0.040 | - | - | - | 1.0 | - |

|

UNS N10673 (Hastelloy B-3) |

65.0 | - | 27.0-32.0 |

1.0 -3.0 |

3.0 | 0.01 | 0.10 | 0.010 | 1.0-3.0 | - | - | 0.030 | 0.20 | 0.02 | 0.02 | Ni+Mo:94.0-98.0 | |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Ductility | HRB |

| UNS N02200 | ||||

| Anneales | 379 | 103 | 40 | - |

| Stress-relieved | 448 | 276 | 15 | B65 |

| N04400(Monel400) | ||||

| Anneales | 483 | 193 | 35 | - |

| Stress-relieved | 586 | 378 | 15 | B65 |

| UNS N06600(Inconel600) | 552 | 241 | 30 | - |

| UNS N06601(Inconel601) | 552 | 207 | 30 | - |

| UNS N06625(Inconel625) | ||||

| Gr.1 | 827 | 414 | 30 | - |

| Gr.2 | 690 | 276 | 30 | - |

| UNS N06690(Inconel690) | 586 | 241 | 30 | - |

| UNS N08020(Alloy 20) | 551 | 241 | 30 | - |

| UNS N08028(Alloy 28) | 500 | 214 | 40 | - |

| UNS N08800(Incoloy800) | ||||

| Annealed | 518 | 207 | 30 | - |

| Cold-Worked | 572 | 324 | 30 | - |

| UNS N08810(Incoloy800H) | 448 | 172 | 30 | - |

| UNS N08811(Incoloy800HT) | 448 | 172 | 30 | - |

| UNS N08825(Incoloy825) | 241 | 586 | 30 | - |

| UNS N06022(Hastelloy C-22) | 690 | 310 | 45 | - |

| UNS N10276(Hastelloy C-276) | 690 | 283 | 40 | - |

| UNS N10665(Hastelloy B-2) | 760 | 350 | 40 | - |

| UNS N10673(Hastelloy B-3) | 760 | 350 | 40 | - |

Packaging & Shipping

Other product series :

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding wire: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Thermocouple alloy: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Inconel alloy: Inconel 600,601,617,X-750,625,690,718,825.

Incoloy alloy: Incoloy 800,800H,800HT,825,925.

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy: Monel 400,K500.

High-temperature alloy : A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Precision alloy series: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Thermal spray alloy: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

![]()

![]()

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . For detail,

please see our update holiday notice. During these period, if you have a demand, Please

send me an email.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Normal order is 10-30days,it depends on customers' quantity.